How To Draw A Worm Wheel

- Drawing Gear Wheels. The names given to the various lines of a tooth on a gear-wheel are as follows: In Figure 233, A is the face and B the flank of a tooth, while C is the point, and D the root of the tooth; E is the height or depth, and F the breadth.

- Efficiency of a worm drive is determined by the lead angle and the number of threads in contact with the worm gear. A high lead angle on the drive reduces frictional losses and heat. A low lead angle reduces gear speed while proportionally increasing torque.

In this quick tutorial you’ll learn how to draw a worm in just a few quick steps, but first There are hundreds of thousands of worm species. They live practically everywhere. Certain worms, such as earthworms, can improve the quality of soil in gardens and on farms. This is very helpful to farmers and gardeners.

Click arrows to page advertsWorm Gears.IntroductionA worm gear is used when a large speed reduction ratio is required betweencrossed axis shafts which do not intersect. A basic helical gear can be used but the powerwhich can be transmitted is low.

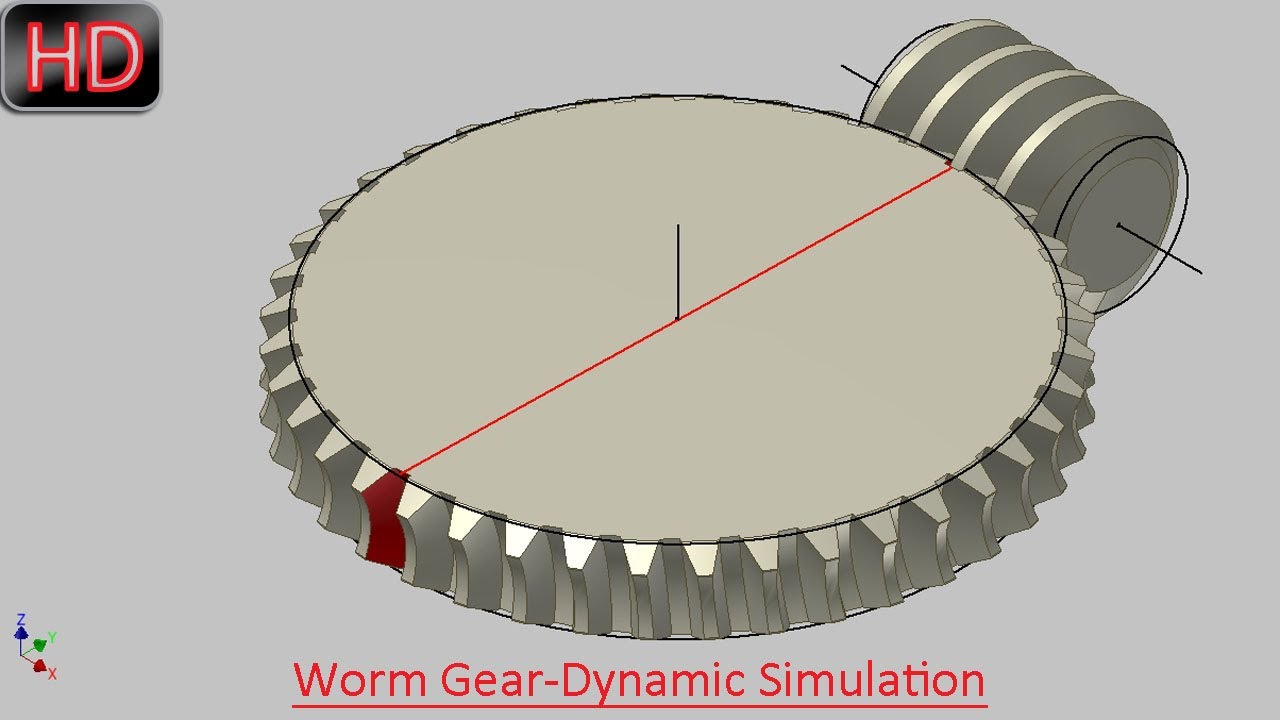

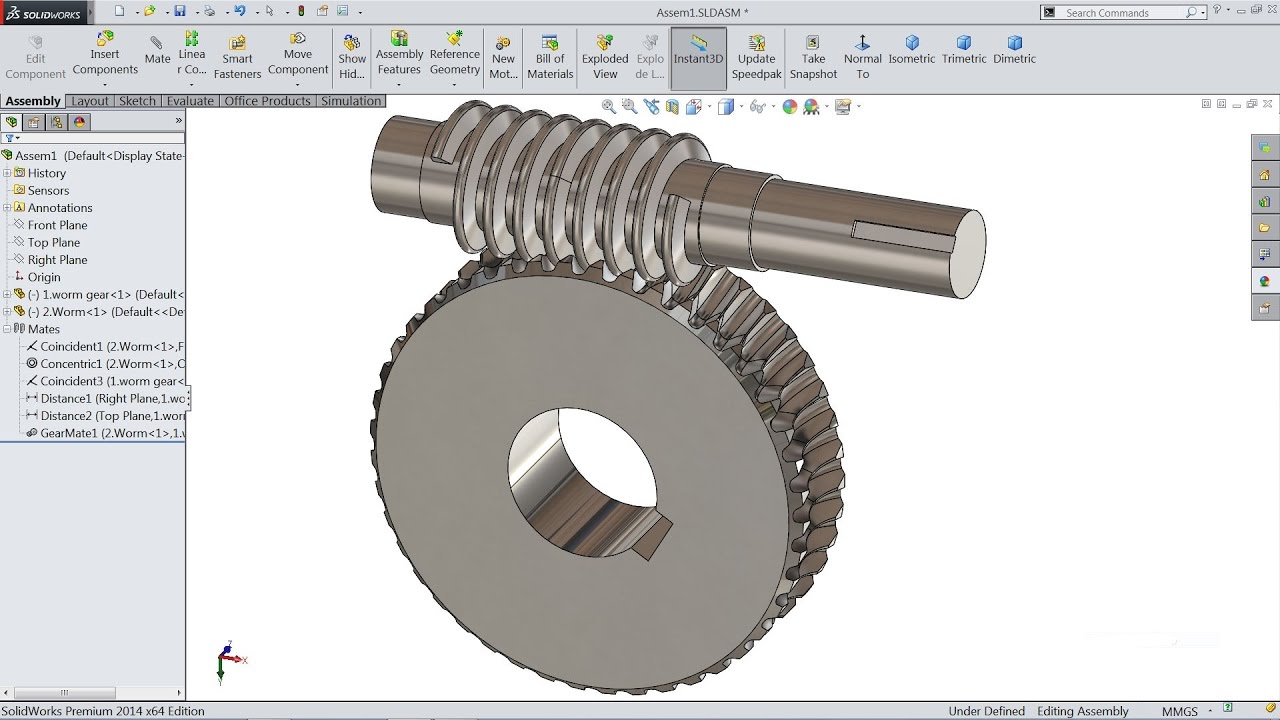

A worm drive consists of a large diameterworm wheel with a worm screw meshing with teeth on the periphery of the worm wheel.The worm is similar to a screw and the worm wheel is similar to a section of a nut.As the worm is rotated the wormwheel is caused to rotate due to the screw like actionof the worm. The size of the worm gearset is generally based on thecentre distance between the worm and the wormwheel.If the worm gears are machined basically as crossed helical gears the result is a highly stresspoint contact gear. However normally the wormwheel is cut with a concave as opposed to a straightwidth. This is called a single envelope worm gearset. If the worm is machined witha concave profile to effectively wrap around the wormwheel the gearset is called a double enveloping worm gearsetand has the highest power capacity for the size. Single enveloping gearsets require accurate alignment ofthe worm-wheel to ensure full line tooth contact.

Double enveloping gearsets require accuratealignment of both the worm and the wormwheel to obtain maximum face contact.Diagram showing the different worm gear options available.The double enveloping (double throat/double globoid ) option is the most difficult to manufacture andset up. However this option has the highest load capacity, near zero backlash capability, highest accuracy and extended life capability.A more detailed view showing a cylinderical worm and an enveloping gear. Wow best hunter addons.

How To Draw A Earthworm

The worm is shown with the worm above the wormwheel. The gearset can also be arranged with theworm below the wormwheel.

Other alignments are used less frequently.NomenclatureAs can be seen in the above view a section through the axis of the worm and the centreof the gear shows that, at this plane, the meshing teeth and thread section is similarto a spur gear and has the same featuresα n = Normal pressure angle = 20 o as standardγ = Worm lead angle = (180 / π ) tan -1 (z 1 / q)(deg).Note: for α n= 20 o γ should be less than 25 ob a = Effective face width of worm wheel. About 2.m √ (q +1) (mm)b l = Length of worm wheel.